For Sale

EGRET

1951 Chesapeake Bay “Deadrise” Skiff

- Year: 1951

- Length: 46′

- Engine/Fuel Type: Single / Gas/Petrol

Located In: Rhode Island, United States

Hull Material: Wood

- Current Price: US$ 485,000

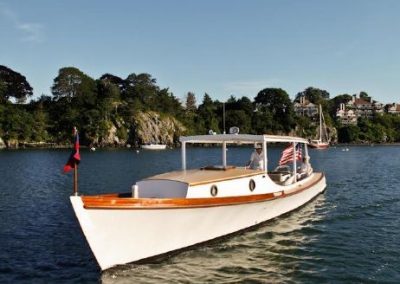

EGRET (Ex-FOUR SISTERS) is a classic 1951 Chesapeake Bay “Deadrise” Skiff built in Shady Side, Maryland. She is a quintessential example of the workboats indigenous to Chesapeake Bay. She is now fully restored and converted to day-cruising, party, and entertainment use.

For more info on the “deadrise” type of workboat design, rarely found outside the Chesapeake, see the brief historical survey at the end of this listing.

EGRET comes to the market from the collection of a passionate yachtsman and expert restorer of significant yachts and antique cars. EGRET remains true to her heritage in terms of her profile, lines, all-wood structure and construction method. However, the objective of her restoration was to transform a faded work and fishing boat into a museum quality vessel to serve as a beautiful and gracious entertaining and day-yachting platform.

At the June 2017 WoodenBoat Show at the Mystic Seaport, CT., EGRET was awarded the “Best in Show – Professional Restoration” prize.

EGRET is sure to provide years of enjoyment and pride of ownership to the enthusiast looking for a historically accurate craft with modern comforts for use as a pleasure day-boat today.

Additional Specs, Equipment and Information:

Boat Name

EGRET (ex-FOUR SISTERS)

Specifications

Builder: Frizzy Atwell

Designer: Robert F. (Frizzy) Atwell

Flag of Registry: United States

Dimensions

LOA: 46 ft 4 in

Beam: 10 ft 2 in

LWL: 44 ft 1 in

Maximum Draft: 2 ft 4 in

Displacement: 12000 lbs Dry Load

Engines

Total Power: 250 HP

Engine 1:

Engine Brand: Chrysler Marine

Year Built: 1995

Engine Model: 318 V-8

Engine Type: Inboard

Engine/Fuel Type: Gas/Petrol

Engine Hours: 139

Drive Type: Direct Drive

Engine Power: 250 HP

Cruising Speed: 14 knots

Maximum Speed: 18 knots

Tanks

Fresh Water Tanks: 2 Fiberglass (70 Gallons)

Fuel Tanks: 2 Fiberglass (70 Gallons)

Holding Tanks: 1 Plastic (6 Gallons)

Accommodations

Number of single berths: 2

Number of cabins: 1

Number of heads: 1

EGRET (Ex-FOUR SISTERS) was designed and built in 1951 by Robert F. “Frizzy” Atwell (1902-1994) – the lead new-construction foreman at the famous Trumpy shipyard in Annapolis. Atwell had been a Chesapeake fisherman early in his career, and occasionally built deadrise boats for his own account at his home at Shady Side, MD (20 miles south of Annapolis), using discarded Trumpy lumber. Effectively, EGRET could be considered a custom Trumpy deadrise – built from Trumpy lumber by a Trumpy foreman.

FOUR SISTERS was built for Ellsworth Brown, an African-American commercial fisherman also based at Shady Side, who had four sisters and named his boat for them. He owned and worked FOUR SISTERS for 35 years. After Brown’s death in 1986, FOUR SISTERS briefly had three other pleasure owners on the Chesapeake. During one of their ownership, FOUR SISTERS’ forward cabin configuration was substantially modified.

By 1993, however, FOUR SISTERS’ days of either fishing or pleasure use were over: she sank at her owner’s home dock in a cove off the Wye River. Before she sank, FOUR SISTERS had attracted the attention of Peter Max, a Washington, DC businessman with a home on the Chesapeake, who had long admired her lines and profile. Max had the boat raised from the bottom in 1994, and brought to the Oxford Boat Yard, then and now one of the most capable wooden-boat yards on the Bay. In a first restoration entailing over 3,000 man-hours of craftsmanship, FOUR SISTERS was completely re-built, and re-launched at Oxford in 1995.

Mr. Max restored FOUR SISTERS meticulously to her original profile and to great structural and cosmetic condition. But he also owned a number of other major boats, including the last Trumpy built. As a result, FOUR SISTERS enjoyed little actual use during his ownership: in the 22 years between her first refit at Oxford and her second refit in 2017, her 1995 Chrysler engine had only clocked 138 hours !

After Mr. Max’s death, FOUR SISTERS was purchased in mid-2016 by a wooden sail- and powerboat enthusiast from Newport, Rhode Island, who had long admired her on the Chesapeake. To the great credit of Oxford Boat Yard, the 1994-95 refit had been so thorough and successful that FOUR SISTERS’ hull still remained in pristine structural condition twenty years later.

The new owner also found that several of the Oxford Boat Yard craftsmen who had participated in FOUR SISTERS’ 1994-95 refit were still active at the yard. So, he asked Oxford Boat Yard (now part of the Brewer chain of marinas and boatyards) to do a second major refit on her – concentrating on mechanical and cosmetic issues.

Thus, in 2016-17, FOUR SISTERS, now re-named EGRET, was again refurbished to state-of-the-art technical, cosmetic, and ABYC standards at Brewer Oxford Boat Yard by some of the same craftsmen who had worked on her 20 years before, as well as their younger colleagues.

After Oxford completed the 2017 refit, EGRET was trucked from Maryland to Rhode Island Mooring Services, North Kingstown, RI, where final cosmetic work was undertaken, including complete painting and varnishing.

At the June 2017 WoodenBoat Show at Mystic Seaport, EGRET was awarded the “Best in Show – Professional Restoration” prize.

REFIT SPECIFICATIONS AND INVENTORY

Unless otherwise indicated, specifications relate to work completed and new components installed during 2017-18 refit.

HULL & EXTERIOR/CABIN

• Now structurally excellent. In 1994-95, hull was substantially reframed and replanked, and cabin house was restored to original 1951 configuration. In 2017-18, a few weak planks in the bottom replaced

• Cabin with 2 V-berths modified to house a sink and toilet, Vacuflush system and holding tank, and new 70-gallon plastic fresh water tank

• Fuel tankage modified to provide additional storage under aft deck

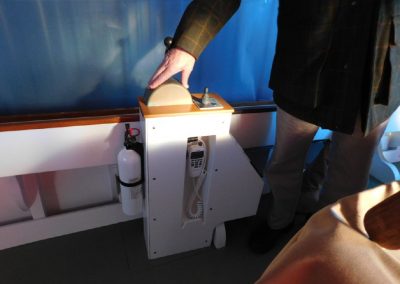

• Custom “Nidacore” engine box, sound- and vibration-insulated with Soundown lead-foam, and Corian top

• Custom integral seating upholstered in Spinneybeck waterproof leather, fore and aft of the engine box, including battery box, hidden panel with battery switches, and drawers

• Topsides entirely refaired

• Bottom paint and seam compound entirely stripped and renewed

• Exterior, cabin, interior, and bottom painted to yacht standards

MACHINERY

• 1995 Chrysler “318” 250hp V-8 gasoline engine refurbished and painted, including: new plugs, wiring, raw water and circulating pumps, manifolds, risers, fuel pump, alternator and starter. At 5/2017, ~ 160 engine hours

• Faria engine instruments

• Engine space ventilation renewed

• Two inline mufflers and two water-lift mufflers (all Vetus)

• Cutlass bearing

• Bronze 4-blade 14” X 18” RH prop

• Kobelt bronze single-lever gear-shift/throttle

• “New Holland Marine” electric “Compact JT-50 Jet Thruster” at the bow

• Push-pull tiller steering refurbished; stainless steel rudder and post

ELECTRICAL SYSTEM

• High-output (85 AH) alternator on the engine

• Chromed 30-amp shore-power intake fixture

• Three “Group 27” marine batteries: one for engine starting, one for the house bank, and one for the bow thruster

• 1995 Guest 215 amp battery charger runs off shore power

• Three small loose solar panels plug into 12 V cigarette lighter outlets near companionway for charging the 3 batteries when engine is off

• Three rotary battery switches: engine-start/bow thruster, house, and “parallel,” located under the custom seating forward of battery box, forward of engine box

• DC and AC breaker panels in the cabin for all service circuits

• All-LED Nav, exterior, and interior lighting

• Courtesy rope lighting under the cockpit side decks, on dimmer

• 12V DC and grounded 110V AC power outlets in the cabin

ELECTRONICS & OTHER NAVIGATION GEAR

• Garmin 742xs touch-screen GPS-plotter on quick-release universal arm, stored in the battery switches compartment

• Air-Mar bronze depth sounder, linked to Garmin screen

• Second Air-Mar bronze depth sounder, linked to Faria digital depth display at helm

• Icom M400 “Black Box” VHF radio in cabin with remote handset at helm

• Loudhailer on roof, linked to Icom VHF radio

• Standard air-pressure horn on roof

• Fusion AM-FM Bluetooth stereo system in cabin. Two deck speakers

• Suunto steering compass at helm

TANKAGE, PLUMBING SYSTEM & RELATED

• 70 gallons total gasoline in two composite tanks under aft deck corners

• Racor filter and bronze manifold system for the fuel system – P cockpit

• Two Faria fuel-tank-level analog displays at the helm (one per tank)

• 70 gallons fresh water in one custom poly tank in the cabin, forward of V-berths

• Jabsco 2.9 GPM fresh water pressure pump

• Cold fresh-water service to stainless steel basin in cabin

• SeaLand “VacuFlush” fresh water toilet with 11-gallon holding tank

• Salt water pressure pump

• Salt- and freshwater hose-bibs in the cockpit

DECK HARDWARE

• Fortress FX 16 aluminum lunch/day anchor with 13’ of galvanized 5/16” chain and 200’ of 1/2″ nylon “Mega-Plait” braided rode – stored under aft deck

• Fortress FX 37 aluminum storm anchor with 20’ of galvanized 3/8” chain and 250’ of 5/8″ nylon 3-strand rode – stored under aft deck

• Oak Samson post at bow, two oak Samson posts at aft deck

• Four custom bronze bow and stern chocks by Jim Reineck

• Two 10” bronze Herreshoff-style mid-deck spring cleats (P & SB)

• Four bronze opening portholes (2 P, 2 SB) in cabin sides

• Two bronze opening portholes (2 P, 2 SB) in front face of cabin

• Two bronze deck prisms in cabin roof to bring natural light below

• Bronze toe-rail banding throughout

• Brass ensign & burgee sockets and teak staffs at stern, bow

INTERIOR IMPROVEMENTS, & FURNISHINGS

• All interior surfaces refurbished and painted

• Stainless steel basin and chromed faucet, cold fresh-water service in cabin

• Six Kingsley-Bate synthetic (all-weather) wicker chairs, 3 hardwood tables on aft deck

• Custom all-weather cushions (all with zippers to facilitate laundering covers)

SAFETY & MISCELLANEOUS EQUIPMENT

• Fireboy engine shut-off and engine-space fire-extinguishing system

• Two stand-alone fire extinguishers, at helm and in cabin

• Two Rule 1,000 GPM bilge pumps on float switches with alarm at helm

• Engine-driven bilge pump connection capability pre-plumbed

• Four fenders with fleece covers

• Eight braid dock and spring lines

• Shaw & Tenney ash and brass boat hook

• Flares per USCG

• First-aid kit

• Ten west Marine inflatable life-preservers in mesh bags

• Substantial tool kit

ADDITIONAL INFORMATION

The Emergence of the Deadrise: An Overview

The first peoples of the Chesapeake Bay, the Powhatan Indians, used dugout canoes to capture fish, oysters, clams, and crabs for food. In the early 1600s, English settlers adopted the Indian dugout canoe, first paddled or poled, then fitted with a sail, to navigate and fish the shallow waters of the Bay and its tributaries.

After the Civil War, as the region’s population grew and standards of living rose, larger sailing canoes were designed to carry heavier loads of clams and oysters. The “Bugeye,” as this type of boat was known, was typically a seven- to nine-log canoe with a full deck, forward cabin, and twin masts.

Eventually, bugeyes became too expensive to build, so watermen switched to frame-planked boats – the “skipjack” and the “deadrise,” the two principal workboat design types on the Chesapeake until World War II and beyond.

“Skipjacks,” typically 40-50 feet in length, had a raked single mast and very long boom. A large sail plan provided power for the skipjacks’ (and later the deadrise’s) main function: pulling oyster dredges, particularly in light air, with minimal crew.

The “deadrise” design emerged in the 1880s from an earlier Chesapeake sail-powered skiff shape, known locally as a “bateau” (French for “boat”). “Deadrise” boats were so called due to the transition from the V-shaped bottom at the boat’s bow to a flat angle between the keel (as it levels off to a horizontal line) and the rise from the keel upward to the chine (or sideboards). Deadrises had shallow draft – only two to three feet – making them practical for use on the shallow Chesapeake Bay and its estuaries.

Early deadrise boats (1900-1910) were mainly 20-30 feet long, for use crabbing. By the 1920s and 1930s, deadrises were used for oystering and fin-fishing, and were somewhat longer: up to 38 feet long; many had round sterns. The 42-footers came next after World War II, as builders were able to get 42-foot-long keels. Then in the 1960s-70s and 80s, 45-50 footers came along to provide the wider/longer hull needed in Virginia’s winter crab dredge fishery. There were also a few unique, far longer deadrises: the 100-foot MARY-DEL was built in the late 1920s by Lin Price of Deltaville.

Deadrise styles were tailored to local needs. Boats for southern areas of the Bay had stronger planking to withstand the rougher, taller waves there. Maryland builders typically used very shallow standard boat shapes, reflecting the Bay’s shallower northern tributaries.

Early Chesapeake deadrise designs also reflected Northeastern, as well as local, influences. After the Civil War, the north’s oyster fields began to be depleted, so New York and New England fishermen in search of new fishing grounds moved to the Chesapeake. They brought with them workboat designs derived from the New Haven “Sharpie” designs of the 1840s, adapted in the workboats of the New York City area and finally blended with the older Chesapeake Bay shapes.

By the late 19th century, essentially industrial boat builders had emerged in Europe and the Northeastern USA. They systematized construction: using drawings or three-dimensional models, and factory methods; and building in volume. By contrast, Chesapeake Bay work boats were traditionally built without drawings, based only on artisanal methods known on the Bay as the “rack of eye.” Deadrise builders typically worked with a few helpers, and built only a few boats per year. They usually sought wood in nearby forests or from local saw-mills, and used simple traditional hand-tools.

As internal combustion engines emerged after 1900, deadrise builders replaced sails with motors adapted from cars, trucks, and factory engines, modifying the boats’ hull shapes to improve performance under engine power. Many older, deadrise boats with gas power are still active on the Bay…but today, diesel power is preferred.

Until after World War II, many areas near the Chesapeake Bay, especially on the “Eastern Shore,” were not widely served by interior roads – so, until a few generations ago, skipjacks and deadrise boats were a principal means of local transportation for much of the rural population, as well as for fishing and carrying freight.

Fiberglass emerged as a boat-building material after World War II. As the costs of lumber and of wooden boat-maintenance rose, wooden deadrise designs were gradually replaced by fiberglass ones, a trend that also led to volume construction of standardized models. Even today, however, one still sees many older wooden deadrise boats on the Chesapeake, especially in the traditional, smaller, local yards.

For more detailed information, see Larry S. Chowning, Deadrise and Cross-Planked, Tidewater Publishers, 2007, on which this general discussion is partially based.

FOR MORE INFORMATION, contact Alec Brainerd at 207-542-0372.